What Is Powder Coating?

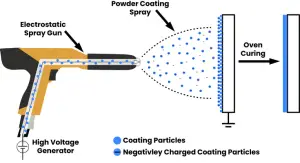

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a surface. The coated object is then heated in an oven, allowing the powder to melt and form a solid, durable finish.

This method is commonly used for coating metals, such as aluminum and steel, in various industries, including automotive, architecture, and home appliances.

The Powder Coating Process: Step-by-Step

- Surface Preparation: The metal surface must be thoroughly cleaned to remove any contaminants like oil, grease, dirt, or rust.

- Application of Powder: The prepared metal is sprayed with a dry powder using an electrostatic spray gun.

- Curing: The coated metal is placed in a curing oven, where it’s heated to temperatures between 350°F and 400°F (177°C to 204°C).

- Cooling: After curing, the coated item is allowed to cool, solidifying the finish and ensuring its durability.

Advantages of Powder Coating

- Durability: Powder-coated surfaces are more resistant to chipping, scratching, fading, and wearing compared to other finishes.

- Environmental Benefits: Powder coatings contain little to no volatile organic compounds (VOCs), making them eco-friendly.

- Variety of Finishes: Powder coating offers a wide range of textures, colors, and finishes, including matte, gloss, and metallic.

- Efficiency: The process is faster and more efficient, with minimal waste and overspray.

Disadvantages of Powder Coating

- Limited Color Matching: Achieving custom colors can be more challenging compared to liquid paints.

- Thickness Limitations: Powder coating may not be suitable for extremely thin layers.

- Equipment Costs: The initial investment for powder coating equipment can be higher than for liquid painting setups.

Applications of Powder Coating

- Automotive Parts: Wheels, bumpers, and chassis components benefit from the durability of powder coating.

- Architectural Elements: Railings, gates, and window frames are often powder-coated for enhanced protection and aesthetics.

- Appliances: Items like refrigerators, washing machines, and other household products utilize powder coating for a durable finish.

- Furniture: Outdoor and indoor furniture pieces are coated to withstand wear and environmental factors.

Powder Coating vs. Liquid Paint: A Comparison

| Feature | Powder Coating | Liquid Paint |

|---|---|---|

| Durability | High resistance to chipping and fading | Prone to scratches and fading |

| Environmental Impact | Low VOC emissions | Higher VOC emissions |

| Finish Options | Limited to available powders | Wide range of colors and effects |

| Application | Requires specialized equipment | Easier to apply with standard tools |

| Cost | Higher initial setup cost | Lower initial cost |

Tips for Successful Powder Coating

- Proper Surface Preparation: Ensure the metal is clean and free of contaminants for optimal adhesion.

- Consistent Application: Apply the powder evenly to avoid inconsistencies in the finish.

- Correct Curing: Follow the manufacturer’s recommended curing times and temperatures for the specific powder used.

- Safety Precautions: Always wear appropriate personal protective equipment, including gloves, masks, and eye protection.

Conclusion

Powder coating is a superior finishing process that offers enhanced durability, environmental benefits, and aesthetic versatility. By understanding the process and its advantages, you can make informed decisions for your projects, whether you’re a hobbyist or a professional.